| Not all flanged connections corrode and fail, not even most, but every site has a handful of flanges that operate under particularly severe conditions. Belzona tends to see some of the worst that industry has to offer and the flanges that we work on while physically small create massive problems for our customers. We can offer repair methods and protective solutions for flanges corroding from the outside in as is the case particularly in acidic atmospheres or the more typical inside out failure mechanism.

Belzona repair compounds are very effective at filling pitting of flange faces which occurs between the flange face and gasket. In the case of very badly pitted flanges, the entire flange face can be recast in situ using an appropriate former as shown in the quick video below. A former can also be used to impart a spiral wound finish to the reformed flange face if a spiral wound gasket is to be used. Once restored, the flange face should be protected with an appropriate coating to prevent recurrence. While it may seem counterintuitive, this protective coating should extend to or beyond the bolt circle. Stopping the coating at the inside diameter of the gasket presents an edge of unprotected metal which can corrode. When steel corrodes it expands in volume at significant pressures which causes the coating nearby to flake off exposing fresh metal. This vicious cycle is called corrosion creep and is easy to prevent in this case; extend the coating beyond the flange. The coating will not crack or prevent the flange from sealing.

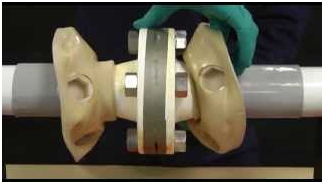

For flanges operating in acidic or harsh environments which are corroding the nuts and bolts holding the flanges together, Belzona has developed a novel system comprised of a release agent containing corrosion inhibitors and a highly flexible brushable coating. The idea is simple enough, release the nuts and bolts using a corrosion inhibitor and encapsulate the flange assembly with a very flexible coating which keeps the environment out but still allows access if needed as shown in the video below.

While not every flange in a facility will require these repairs, Belzona has tremendous confidence and success with field repairs of problematic flanges. Please do not hesitate to contact us for additional information or to set up an inspection.

Chris Lucas

clucas@rumfordgroup.com

937-435-4650

RumfordGroup.com

Time sure does fly, 35 years have gone by On January 11, 1980 Rumford Industrial Group was incorporated, becoming the Great Lakes Region distributor for Belzona® polymeric repair compounds and industrial protective coatings. We are honored to know that you rely on us to repair, protect and improve your machinery, equipment, buildings and structures when things stop working. We trust that you’ll allow us to continue to be a trusted business partner for the next 35 years and beyond. On behalf of our employees and associates, thank you so very much for the opportunity to be of service. Jim Rumford

Newsletter Subscription and Archives Newsletter Subscription and Archives

In keeping with our mission of “aggressive growth through education of clients and associates on solutions to Repair, Protect and Improve their physical assets”, we offer industry specific newsletters that target cost saving applications specific to your particular needs. Please take a moment to subscribe to any of the sixteen newsletters by clicking on the “Subscribe” button or check out our archives by clicking on the “View Archives” button. We also welcome any comments, thoughts or ideas you may have.

In-Plant Seminars In-Plant Seminars

Hit the "FREE In Plant Seminar" button above and we’ll swing by your site to discuss Belzona® polymer repair and protective coating solutions that can extend the service life of your equipment and infrastructure. We’ll even bring you lunch!

|